TRACKFLEX

PRODUCT SUMMARY

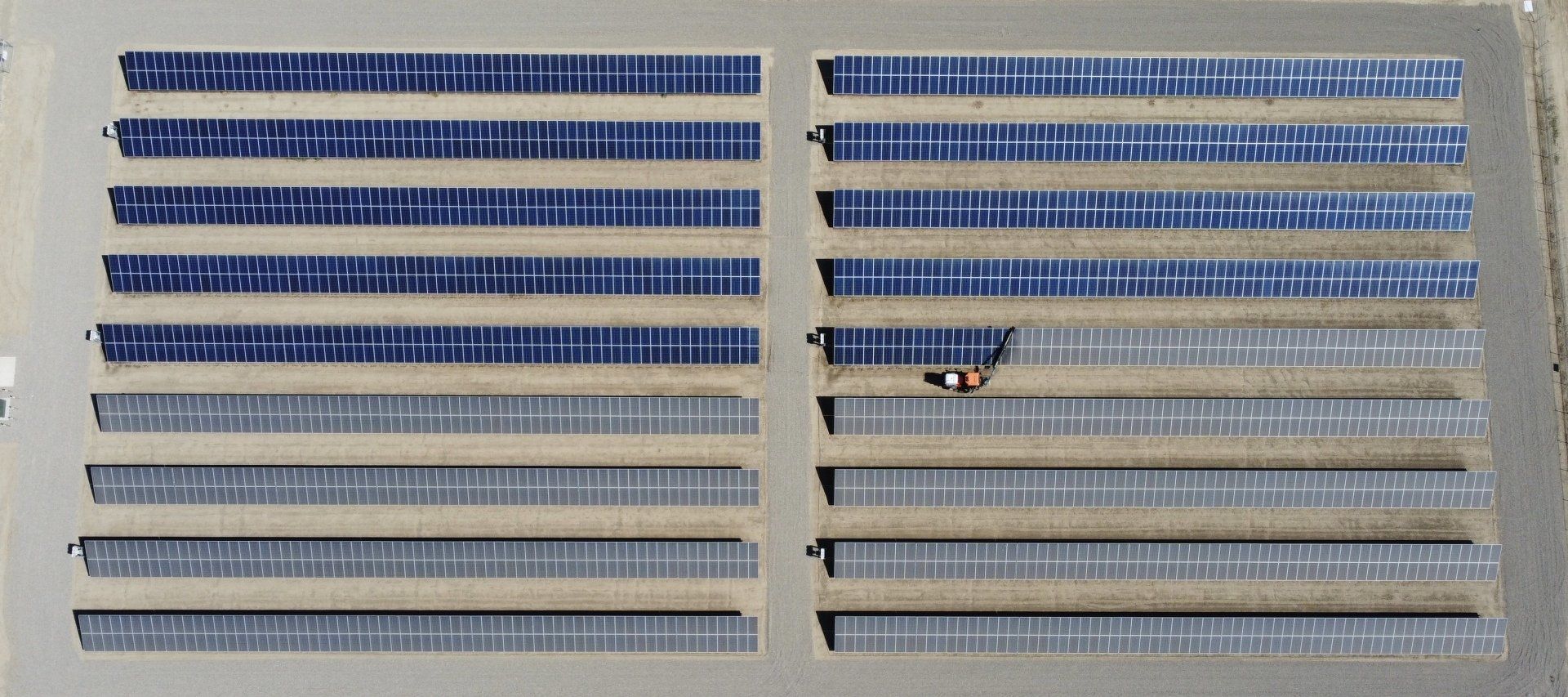

The TrackFlex is the most flexible and versatile SunBrush yet. Specifically designed for sites with trackers or narrow rows, the main boom can bend on the go using the intuitive SunBrush joystick. With a TrackFlex no site is too difficult for SunBrush to clean.

The bending feature brings the carrier vehicle closer to the panels, whilst also enabling the cleaning of trackers 24/7, even when almost flat. Cleaning with the panels at an angle is recommenced, to allow the dirty water to flow off the panel, but not essential.

Mountable on a wide range of carrier vehicles, we can create a system to suite your needs. Optional Changing Arms are available to enable different brush lengths for the same machine, offering more flexibility. SunBrush’s effective “WashTronic” float system enables the brush to keep a constant yet limited pressure on the panels, resulting in damage free operation.

PRODUCT SUMMARY

- One operator cleaning MW’s per day

- Modular Cleaning system

- Float system to ensure constant cleaning pressure and affect.

- 10ft, 15ft, 20ft, 25ft Brushes

- 14” Brush Diameter as standard

- Optional NexTracker 20” Brush

- PTO Water Pump as standard for integrated wet

SUITABLE CARRIER VEHICLES

- Agricultural Tractor w/ front 3 point linkage

- Eg. John Deere, Kubota, Case, Fendt, Deutz

- Skid Steer (Tracked Mini Loader)

- Eg. Bobcat, John Deere, Case, Caterpillar

- MultiHog Utility Tractor

- Telescopic Handle

- Norcar Tracked Mini-Loa